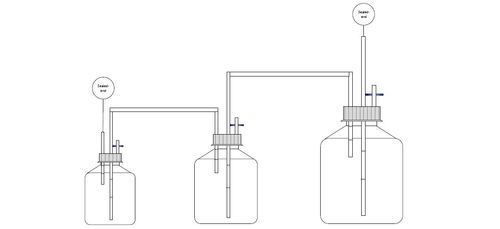

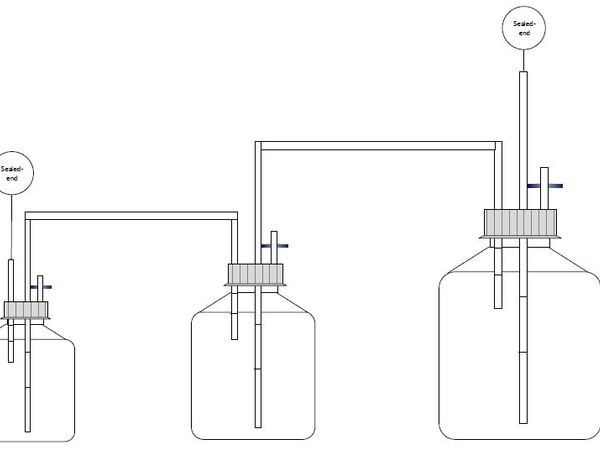

Assembly seed train threefold

When you grow cell cultures, it is important that you can transport them to a larger vessel without the risk of contamination. At Hitma you can put together your own gamma-irradiated seed train set-up.

Quality

Our single-use fill & finish assemblies consist of high-quality components as standard, such as:

- Foxx bio-bottles with EZ top connection

- Saint-Goban Bio-simplex bottles.

- C-flex weldable TPE tubing

- Eldon James hosebarb fittings

- Clip on Nordson PharmaLok tube

- Zenpure filters

All these components are qualified for use in cGMP environments. They are made of materials that comply with USP class VI and have well-documented extractable profiles.

Sterility

These seed train assemblies are assembled in our own cleanroom according to validated procedures. The assemblies are part of our sterility program, which allows us to give a sterility claim on our gamma-irradiated assemblies.

Open architecture

In addition to our own standard range of single-use components, we can integrate every component according to your specifications - as long as the components meet our minimum quality requirements.

Flexibility

The assembly in the drawing is an example. We can manufacture any desired design. You can supply a drawing yourself, or have one of our specialists make a design based on your application. After agreement on the design we can produce the assembly in any desired amount, with short delivery times.

Do you want to know more about these assembled and irradiated seed train assemblies? Contact us via chat, email or by phone.