Assembly Fluid transfer TC

The sanitary fitting is one of the most reliable and commonly used connection methods in the pharmaceutical production process. Two sanitary fittings - with a gasket placed in between - are secured with a tri-clamp. This ensures a leak-free connection that enables you to link different process steps.

Quality

At Hitma we work with high-quality materials. You can choose from a wide range of sanitary fittings, tubings and tri-clamps. Of course we are happy to advise you about the materials.

When working with high pressure or vacuum, you can opt for a crimped sanitary fitting of stainless steel in combination with reinforced tubing. Reinforced tubing uses braided fabrics and metal wire so it can be used under more demanding conditions. Hitma is certified for crimping sanitary stainless steel fittings.

If you do not work with high pressure or vacuum, plastic sanitary fittings are a cost-effective alternative.

We work with:

- Saint-Gobain 316L SS stainless steel sanitary fittings

- Nordson Medical plastic fittings (polypropylene or PVDF)

- Nordson Medical single-use Tri-clamps

- SGPPL Tygon and Sani-Tech (reinforced) silicone tubing or TPE tubings like C-flex and Pharmed BPT

- Newman gaskets (Silicone, EPDM or Viton)

All these components are qualified for use in cGMP environments. They are made of materials that comply with USP class VI and have well-known extractable profiles.

Sterility

The fluid transfer assemblies with sanitary fittings are made in our cleanroom according to validated procedures. If desired, a sterility claim can be given on the gamma-irradiated assemblies.

Open architecture

In addition to our own standard range of single-use components, we can integrate every component according to your specifications - as long as the components meet our minimum quality requirements. You can therefore specify single-use tubing, a TC-clamp or another connector to have a single-use assembly made exactly to your wishes and requirements.

Flexibility

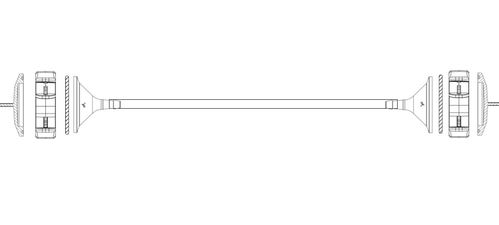

The assembly in the drawing below is an example. We can make any design you desire. You may supply a drawing yourself, or have one of our specialists make a design based on your application. After agreement on the design we can then produce the assembly in any desired amount, with short delivery times.

Want to know more about these assembled and irradiated fluid transfer assemblies? Contact us via chat, email or by phone.